If you have ever had a piece of timber removed from your property, it is quite possible that some laser marking had to be done. Although there may have been many occasions when laser markings have been required, can laser marks be removed? The answer is yes, but not without a bit of help. There are many products on the market today, which can help with this process. And in many cases, these products are effective and will get the job done.

What is Laser Marking

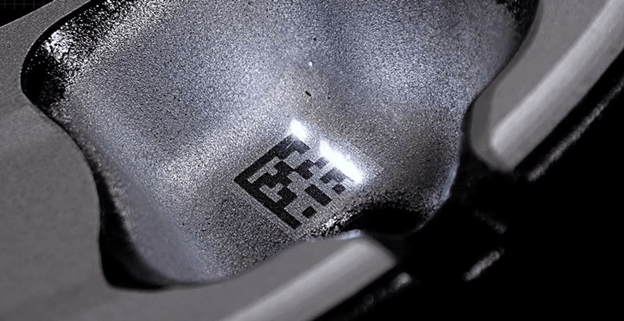

Before delving into the question, it would be wise to understand precisely what laser marking is and how it can be applied. Marcatrici laser prezzo is simply any marking applied to timber that has been laser cut. This may include saw marks, stamping, or engraving. It can also involve applying colored paint to a wooden beam or floor. This can all be done without the use of an actual laser but rather a chemical such as epoxy or varnish. Once the chemical is applied to the wood, it will penetrate the surface of the timber and create a color of light or dark.

Many contractors and experts believe that laser marking applied to timber is inevitable. However, there is no hard evidence to prove this. As long as the wood is prepared correctly before it is laser cut, it is likely that laser markings will occur.

Also, read How to be creative with Herringbone Flooring?

Timber Specialist

In most cases, the contractor will contact a timber specialist to do the work for them. Once the job is completed, the specialist will take measurements, photos, and videos of the timber to identify any imperfections in the cut. These will then be compared to the pre-cut print, and the laser marking will be done. In many cases, laser marking can be removed by sanding the timber smooth and using a high-quality filler to fill any voids that may have developed.

Although some timber beams are more complex than others to cut using a laser, it is worth using a laser marking tool if at all possible. This is because even a tiny error when marking timber can impact its final appearance. Plus, laser Prezzo will help ensure that the timber beam looks completely uniform and flat.

Low Heat Aluminum

A skilled tradesperson or timber worker can still remove laser markings from timber beams by hand if a laser Prezzo is not available. This may not be possible if the timber beam has been shaped or routed before being laser cut. In this case, a low heat aluminum oxide laser will help remove the laser marks reasonably easily. The laser itself will be held under a black flag, so it cannot be seen. The laser’s heat can melt the flag, and the individual beams of timber can be laid horizontally back in place.

Cutting Process

There is a slight disadvantage to using a manual way to laser mark timber: it might be possible that some of the laser markings become distorted during the cutting process. This may be especially true if there is a lot of timber to be removed or if too many pieces of the beam are required to be removed at one time. However, laser marking can still be a perfect choice for replacing a laser Prezzo or for repairing a laser beam that has been damaged.

Last Words:

A professional laser resurfacing company can also offer other options besides laser Prezzo and timber beam removal. These include the removal of mold and mildew. They can also apply varnish to timber to improve its appearance after it has been laser marked. A skilled laser resurfacing company can perform stain removal using a chemical and a high-pressure jet of water. These are all options that can be used to give a finished look to a timber beam or repair a laser Prezzo that has become damaged.